"Understanding Variation (7)" described how process tampering negatively impacts productivity. Tampering increases variation and reduces Quality. Tampering may be the result of operators or management actions. Can a Process Behavior Chart (control chart) help?

COOKIES (real ones)

My wife buys me thick choc chip cookies. Some are fantastic but some batches are dry and hard enough to break one's jaw. There is major variation in moisture content.

Suppose an astute operator noticed the cookies were coming out of the oven too moist. He might tweak the oven temperature up. If they seemed too dry, he might turn the oven down a bit. This is tampering. It makes things worse. Can management detect what has been happening with a Process Behavior Chart?

It depends. This form of tampering can be one of two types, Mode 2 or Mode 3. In both modes there is an adjustment equal but opposite in direction to the change. In mode 2, the adjustment is from the last position. In Mode 3, the adjustment is from the target position.

COMMON vs ASSIGNABLE CAUSES

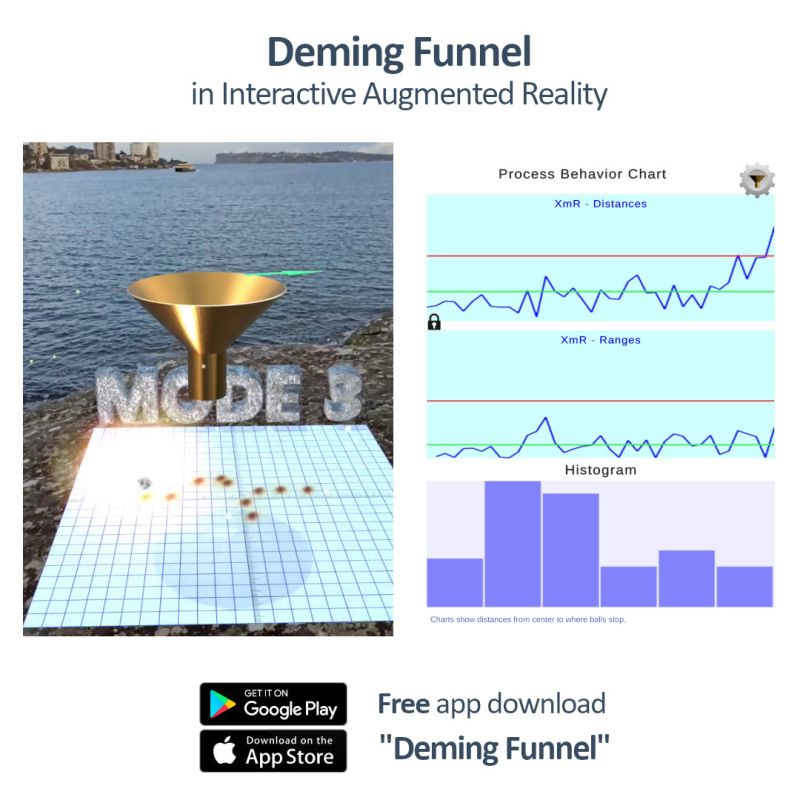

Mode 2 tampering is a common cause, yet Mode 3 tampering is an assignable cause! I would never have guessed, until I became engrossed in testing our new Deming Funnel in Augmented Reality app.

In other words, Mode 3 tampering can be immediately detected with a Process Behavior Chart but it is much more difficult with Mode 2 tampering. Mode 2 tampering firstly requires a chart with zero tampering. This can then be compared. In both modes, tampering increase variation. Mode 3 tampering may even seem to disappear, then reappear.

It is essential for every employee to have a thorough grounding in Quality so that common cause variation is not treated as an assignable cause.

COOKIES

The first step with any process should be a Process Behavior Chart. If assignable causes appear, they should be investigated immediately. One possible cause may be tampering.

SHEWHART

It is important to appreciate that control limits are ECONOMIC limits. "As already stated, the object of control is to enable us to do what we want to do within economic limits." - Dr Shewhart.

Most people make the 2 common mistakes that Dr Shewhart identified:

1. Ignoring assignable causes a passing mischance.

2. Reacting to common cause variation as though it were special.

Tampering is the result of a failure to identify common cause variation. Mode 2 tampering is particularly insidious because it is difficult for management to identify it after the fact.

All employees need to be trained with an understanding of variation so that all tampering can be eliminated.

FREE DEMING FUNNEL APP

You can experience the effects of tampering with our new Deming Funnel in Interactive Augmented Reality app, now available in the apps stores. In the interest of helping bring the world back to Quality, the app is FREE.

I'd very much appreciate your feedback.<

by Dr Tony Burns BE (Hon 1) PhD (Chem Eng)

by Dr Tony Burns BE (Hon 1) PhD (Chem Eng)